Inspections with FIFISH ROV

1970-01-01

Redefining Efficiency and Safety Standards for Hull Coating Inspections

Shenzhen · September 2023

Background & Key Challenges: Setting Higher Standards in Hull Evaluations

A globally leading marine coatings company in Shenzhen has encountered new challenges in ensuring the quality and durability of anti-corrosion coatings for a large cargo vessel. Measuring 400 meters in length, the vessel requires inspections for corrosion, peeling, and marine fouling risks. Traditional diver inspections are time-consuming and pose significant safety risks in murky or fast-moving waters. To obtain more timely, accurate, and actionable data, the company urgently needed an advanced and highly reliable solution.

FIFISH Underwater ROV Inspection Solution: Multifunctional Capabilities with Integrated AI Algorithms

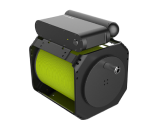

After thorough evaluations, the client selected QYSEA’s FIFISH ROV—a specialized inspection solution built for high-precision operations in complex marine environments. Its 360° omnidirectional mobility, combined with a 4K ultra-wide fisheye lens (176° field of view) and a 10,000-lumen illumination module, enables it to capture detailed images even in low-visibility conditions. Multi-dimensional inspection modes, including “S” pattern, cross-line, and horizontal scans, ensure thorough coverage of every part of the hull. Most notably, its AI-driven analytics and anomaly detection features allow real-time identification of suspected damage or corrosion points, with millimeter-level precision measurements of the affected areas. The system automatically generates inspection reports, providing critical data for subsequent maintenance.

Redefining Efficiency, Safety, and Accuracy in Maritime Inspections

The ROV’s remote control and real-time image streaming capabilities significantly accelerate the inspection process compared to traditional diver-based methods, while also reducing the safety risks for divers or the need to dry-dock the vessel. Thanks to its modular design and the ability to operate 24/7 using four battery modules, the entire system exhibits stable performance, easy maintenance, and quick deployment. Coupled with its AI-powered detection capabilities, it not only boosts the rate of identifying coating anomalies but also saves considerable time and costs for subsequent ship repairs and maintenance.

This successful application of the FIFISH ROV for coating inspections proves that cutting-edge underwater robotic technology can rapidly bolster vessel maintenance and industry safety, setting a higher benchmark for future maritime operations.