-

Entry-Level

FIFISH V-EVO

360° OmniView underwater drone, with a 4K · 60FPS high frame-rate camera & multi-tool integrations

FIFISH V6s

360° omnidirectional 4K underwater drone with a robotic claw module & enhanced battery capacity

FIFISH V6

World’s first 360°omnidirectional underwater drone, with a 4K camera & VR head tracking controls

FIFISH V6

World’s first 360° omnidirectional underwater drone, with a 4K camera & VR head tracking controls

FIFISH P3

Professional underwater camera robot with 4k UHD quality, 20 MP resolution & 1-inch CMOS sensor

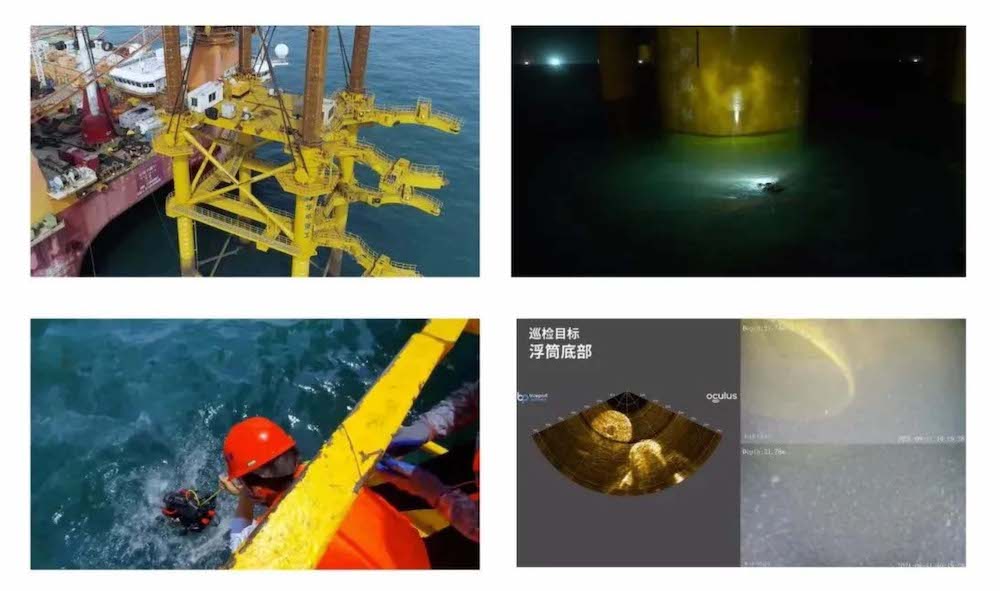

Professional & Industrial

FIFISH E-MASTER

Industrial Class, Advanced Inspection · Measurement · Survey, Compact AI Underwater Robot

FIFISH E-GO

Professional-class, fully-modular, multi-functional & high-performance OMNI · 4K underwater operational robot

FIFISH V6 EXPERT

Professional-class, high-performance & multi-functional OMNI · 4K underwater drone & subsea productivity solution

Enterprise

FIFISH PRO V6 PLUS

Enterprise-grade & small-sized OMNI · 4K smart Underwater ROV, with 150-meter depth rating & multi-tool integrations

FIFISH PRO W6

Enterprise-grade & mid-sized OMNI · dual 4K smart Underwater ROV, with 350-meter depth rating & multi-tool attachment capabilities

FIFISH PRO ZEN1

Professional-class cinematic Underwater ROV platform, with multi-tool attachment capabilities & integrated camera housing

Consumer · ProfessionalFIFISH E-MASTERIndustrial Class, Advanced Inspection · Measurement · Survey, Compact AI Underwater RobotFIFISH E-GOProfessional-class, fully-modular, multi-functional & high-performance OMNI · 4K underwater operational robotFIFISH V-EVO360° OmniView underwater drone, with a 4K · 60FPS high frame-rate camera & multi-tool attachmentsFIFISH V6 EXPERTProfessional-class, high-performance & multi-functional OMNI · 4K underwater drone & subsea productivity solutionFIFISH V6s360° omnidirectional 4K underwater drone with a robotic claw module & enhanced battery capacityFIFISH V6World’s first 360°omnidirectional underwater drone, with a 4K camera & VR head tracking controlsFIFISH P3Professional underwater camera robot with 4k UHD quality, 20 MP resolution & 1-inch CMOS sensorEnterpriseFIFISH PRO V6 PLUSEnterprise-grade & small-sized OMNI · 4K smart ROV, with 150-meter depth rating & multi-tool attachment capabilitiesFIFISH PRO W6Enterprise-grade & mid-sized OMNI · dual 4K smart ROV, with 350-meter depth rating & multi-tool attachment capabilitiesFIFISH PRO ZEN 1Professional-class cinematic ROV platform, with multi-tool attachment capabilities & integrated camera housing -

-

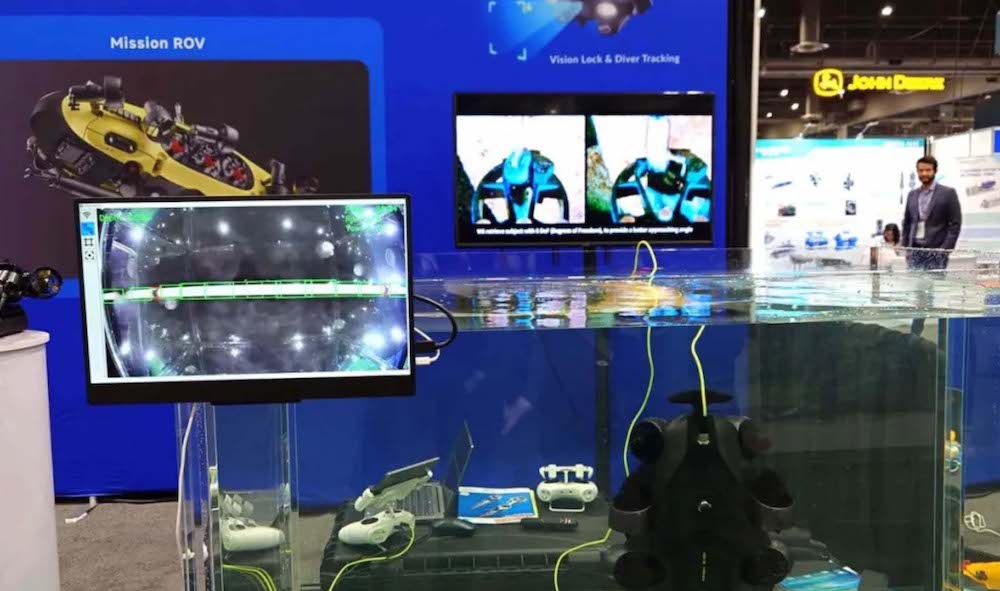

Inspect

Q-Camera

Real-time video feed and onshore control with multi-angle installation.

-

Retrieve

Robotic Arm

Retrieve, move and recover underwater objects with power and precision.

-

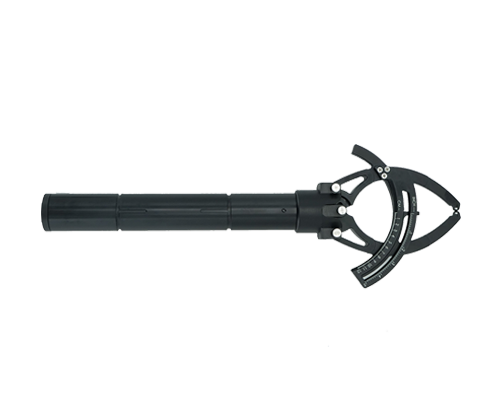

Measure

Compass Ruler

Measure the size of objects for subaquatic operations, explorations, and inspections.

-

Sample

Water Sampler

Collect water samples across diverse environments at up to 350m below sea level.

-

Navigate

U-QPS

(Underwater GPS)Underwater real-time location tracking, points of interest (POI) labeling, and more.

-

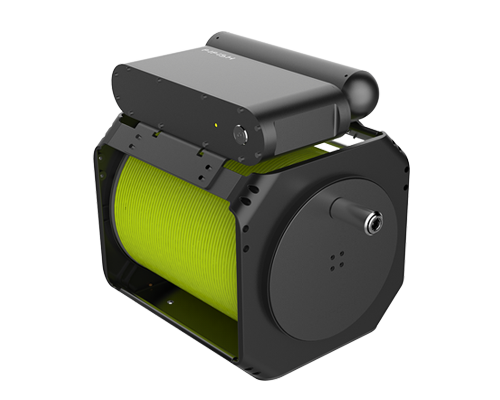

Enhance

Onshore PowerCharge

Source SystemSimultaneous quick-charging and operational capabilities for the FIFISH ROV.

Onshore Power Supply SystemSimultaneous operating & charging system for enhanced usage lengths & uninterrupted diving sessionsUnderwater Quick Positioning SystemSoftware & hardware ecosystem that retrieves data on the FIFISH ROV’s real-time location, POI & dive path recordings & moreOther Add-on Tools & EquipmentLearn about additional attachments for your exploration, inspection, maintenance & filmmaking needs -

- CONTACT US